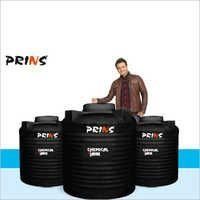

Chemical Storage Tanks

1200.00 - 12000.00 INR/Piece

Product Details:

- Processing Rotational Molding

- Capacity 5000 Liters

- Grade Industrial Grade

- Tolerance 2% of dimensions

- Condition NEW

- Dimension (L*W*H) 1200mm x 1200mm x 1500mm

- Application Storage of chemical liquids and solutions

- Click to View more

X

Chemical Storage Tanks Price And Quantity

- 1 , , Piece

- 1200.00 - 12000.00 INR/Piece

Chemical Storage Tanks Product Specifications

- Industrial Grade

- 1200mm x 1200mm x 1500mm

- NEW

- 2% of dimensions

- Storage of chemical liquids and solutions

- Rotational Molding

- 5000 Liters

Chemical Storage Tanks Trade Information

- 25000 , , Piece Per Month

- 7 Days

Product Description

Chemical Storage Tanks offered by us, are used for removal of all unwanted chemicals and in complete purification. These tanks are offered in both standard and customized options are presented in technically advanced series to our clients. These tanks are used for processing of chemicals and acids. These are categorized as cylindrical vertical conical bottom. Chemical Storage Tanks are very cost effective and they require very low maintenance and operating costs.

FEATURES

- Store from 500 to 5000 liters tank type dependent

- Chemical and Corrosion resistant systems

- Best Row Material

- Reasonable Cost

- Made using latest manufacturing technique.

- Long Life

Exceptional Durability and Chemical Resistance

Constructed from industrial-grade HDPE, this storage tank boasts excellent resistance to a wide range of chemicals and environmental factors. Its smooth, non-porous surface, and robust 8 mm thick walls prevent leaks and deterioration, even under harsh operating conditions. UV stabilization adds further protection, making it reliable for long-term outdoor use.

Designed with Safety and Convenience in Mind

The tanks cylindrical vertical shape and precise rotational molding manufacturing ensure structural strength and stability. Fitted with a 450 mm manhole for convenient inspection, along with dedicated inlet, outlet, and drain provisions, the tank makes chemical handling both safe and straightforward. Its above-ground design simplifies installation and maintenance.

FAQs of Chemical Storage Tanks:

Q: How should the HDPE chemical storage tank be installed?

A: This tank is intended for above-ground installation on a level, sturdy surface. Ensure the site can support the filled tanks weight and is easily accessible for maintenance, inspection, and chemical transfer.Q: What types of chemicals can be stored in this HDPE tank?

A: The tank is made from industrial-grade high-density polyethylene, offering excellent corrosion resistance and compatibility with a wide variety of chemical liquids and solutions commonly used in industrial processes.Q: When is the best time to perform inspections or maintenance?

A: Regular inspections should be scheduled according to the type of chemicals stored and the frequency of use. It is recommended to inspect the tanks fittings, manhole, and surface finish at least every six months for optimal safety and performance.Q: Where can this tank be used most effectively?

A: This storage tank is suitable for industrial facilities, laboratories, and manufacturing plants across India where chemical storage is required. Its UV-resistant and leak-proof features make it ideal for both indoor and outdoor applications.Q: What is the process used to manufacture the tank, and how does it benefit quality?

A: The tank is produced using rotational molding, ensuring an even wall thickness and a seamless, leak-proof structure. This process improves structural integrity and extends the lifespan of the tank during demanding chemical storage duties.Q: How does the tanks design promote safety and ease of use?

A: Featuring a 450 mm manhole for inspection, dedicated inlet, outlet, and drain fittings, and a smooth surface for easy cleaning, the tank is optimized for safe, efficient handling and maintenance.Q: What are the main benefits of choosing this tank for chemical storage?

A: Users benefit from its robust corrosion resistance, UV protection, leak-proof design, and industrial-grade durability. Its ample 5000-liter capacity, precise dimensions, and ease of installation make it a reliable choice for secure chemical storage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

PRINS POLYTECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |